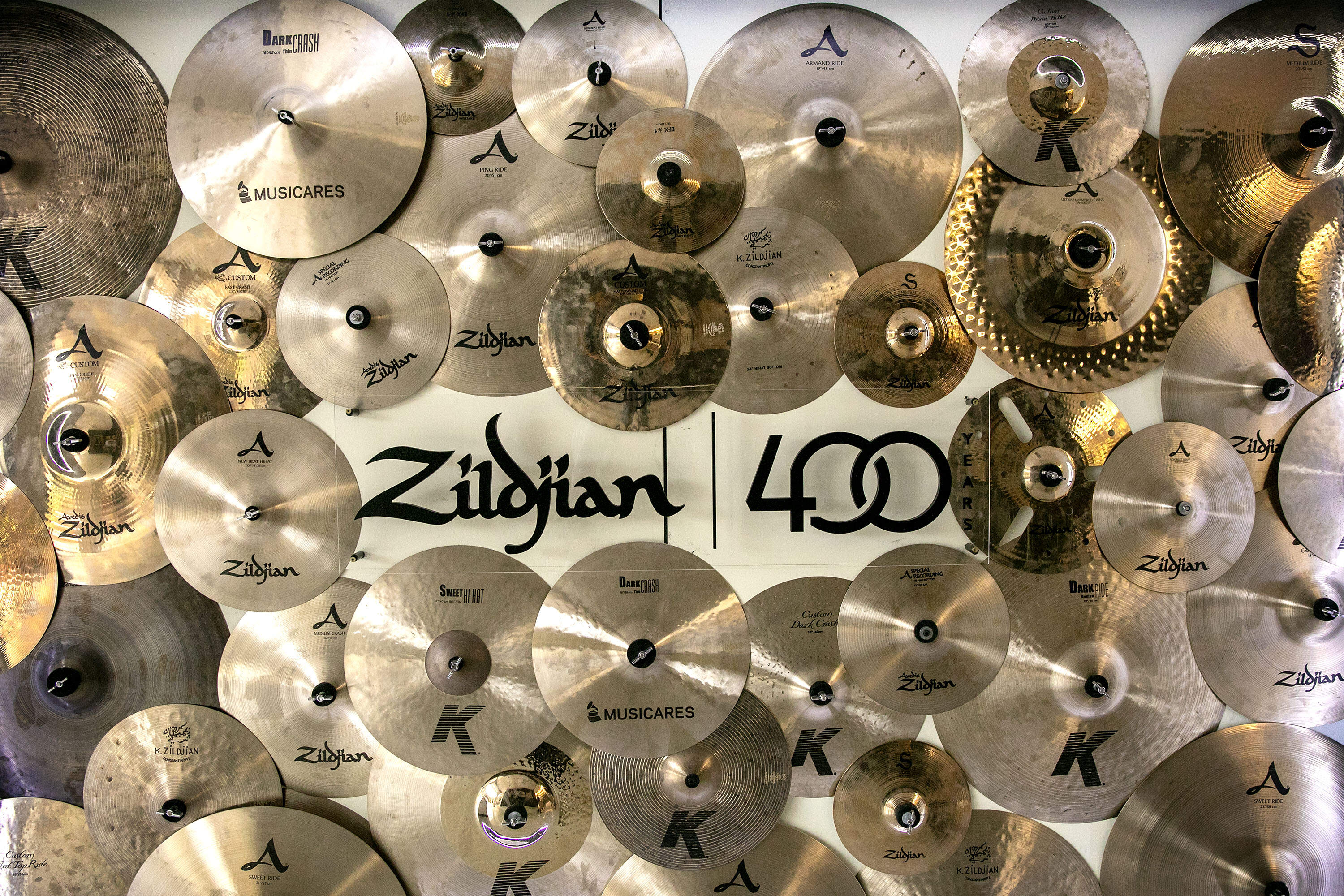

From symphonies to rock music, marching bands and promoting jingles — we hear Zildjian cymbals in every single place. Drummers throughout the globe know that title as a result of it’s emblazoned on each gleaming disc. What’s much less recognized is the Zildjian household has been making their well-known cymbals — with a secret course of — for greater than 400 years.

Because the Seventies, the Avedis Zildjian Co. has operated beneath the radar in Norwell, Massachusetts. We jumped on the likelihood to get contained in the world’s oldest cymbal producer.

Even in Massachusetts many individuals do not know an industrial manufacturing facility outdoors of Boston designs, casts, blasts, rolls, hammers, buffs and assessments no less than 1,000,000 Zildjian cymbals every year.

“There’s numerous mystique and numerous historical past at this facility,” stated Joe Mitchell, the corporate’s director of operations, as we walked previous loud, hulking equipment. He’s one of many few aware about a Zildjian course of that’s been shrouded in thriller for the reason that peak of the Ottoman Empire. It begins in a room that’s off-limits to the general public.

“Behind this door is the place we’ve got our foundry,” Mitchell defined. “That is the place we soften our steel and the place we pour our castings. I will present you what the castings appear like — however clearly we will not transcend this level.”

He leaned over a bin crammed with chunky, rough-hewn steel discs. Even of their nascent state, Mitchell stated the castings possess the key to Zildjian’s sound. He struck one calmly to launch a fascinating, reverberant ring.

The corporate’s proprietary alloy was alchemized 13 generations in the past in Constantinople (now Istanbul) by Debbie Zildjian’s ancestor, Avedis I. He was attempting to make gold, she stated, however he ended up concocting a mixture of copper and tin. “The blending of these metals produced a really loud, resonant, stunning sound,” she stated.

Debbie defined that in 1618 the Ottoman sultan summoned Avedis to the Topkapi Palace to make cymbals for elite army bands. The metalsmith’s work happy the ruler, who gave him permission to discovered his personal enterprise in 1623. The sultan additionally bestowed Avedis the household title “Zildjian” which truly means cymbal maker. He went on to craft cymbals that had been extensively used, together with in church buildings and by stomach dancers.

By the 1700s European composers, together with Mozart and Haydn, added Zildjian cymbals to their symphonies. “So, that is how the repute grew,” Debbie stated.

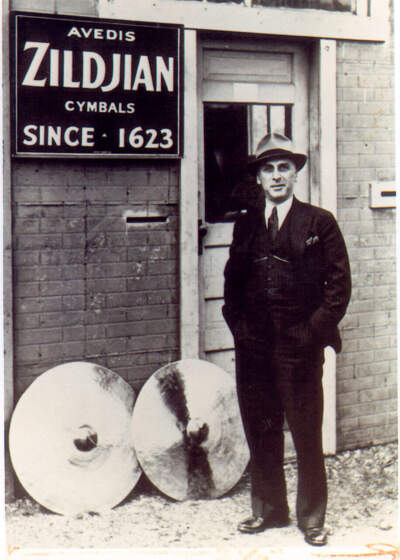

Zildjian turned synonymous with cymbals after her grandfather Avedis III, an ethnic Armenian, emigrated to the U.S. in 1909. 20 years later he re-located the household’s cymbal enterprise from Turkey to Quincy, Massachusetts together with his uncle.

On the time jazz was exploding, so Avedis III travelled to New York Metropolis so he may develop new sounds with pioneers, together with Gene Krupa. “Not solely was he a superb drummer,” Debbie stated, “he was additionally very flamboyant in his type.” This made Krupa a really perfect ambassador for Zildjian.

The corporate actually took off with a bit of assist from The Beatles’ 1964 look on the Ed Sullivan Present. “Everyone wished to change into a musician,” Debbie stated, “and it was in a matter of months that we had been completely backordered as a result of Ringo was an enormous celeb. In order that catapulted our enterprise into the fashionable period.”

In 1973, Zildjian moved to a state-of-the-art manufacturing facility in Norwell. Debbie stated her father Armand, who was then operating the corporate, liked music like his personal father. “What my father actually understood — and sort of preached to all of us right here — was we’ve got to observe the music,” she stated.

Armand, who began working in Zildjian’s soften room when he was 14, finally introduced Debbie and her sister Craigie inside to show them the key course of. The household enterprise had at all times been handed right down to the eldest male, however Debbie and Craigie had been their father’s heirs.

“For us, it was very pure on the within, however the music trade had a tough time accepting girls within the enterprise,” Debbie stated. “The gamers had been all males, manufacturing was accomplished largely by males, the salespeople had been all males.”

Craigie turned CEO in 1999. Now she’s president and govt chair of the board of trustees. Debbie gravitated to manufacturing and oversees Zildjian’s proprietary alloy course of taught to her by her father.

Over the a long time, drummers throughout all genres have embraced Zildjian cymbals – from Lars Ulrich of Metallica to Grammy Award-winning jazz drummer Terri Lyne Carrington.

“I usually play about six cymbals plus hi-hats,” she stated, “They’re the sound I’ve been enjoying my complete life as a result of most jazz drummers play Zildjian cymbals.”

Carrington based and directs Berklee Faculty of Music’s Institute of Jazz and Gender Justice in Boston. She’s additionally a Zildjian artist, which implies she solely endorses and performs the corporate’s cymbals. Carrington stated they’ve helped forge her musical id since she was 10 years outdated.

“Your cymbals are your signature,” she defined. “So everytime you play, you are usually acknowledged by your cymbal sound, and your contact, and your cymbal patterns — no less than in jazz.”

Carrington’s drum package is sort of a painter’s palette. The sound of every cymbal guides her to the subsequent stroke. She’s visited the Zildjian manufacturing facility many occasions and nonetheless marvels at what they do. “I don’t know the key sauce,” she stated, “however to make a chunk of steel sound so fairly — and change into this stunning instrument that is part of each sort of music that you just hear — is fairly exceptional.”

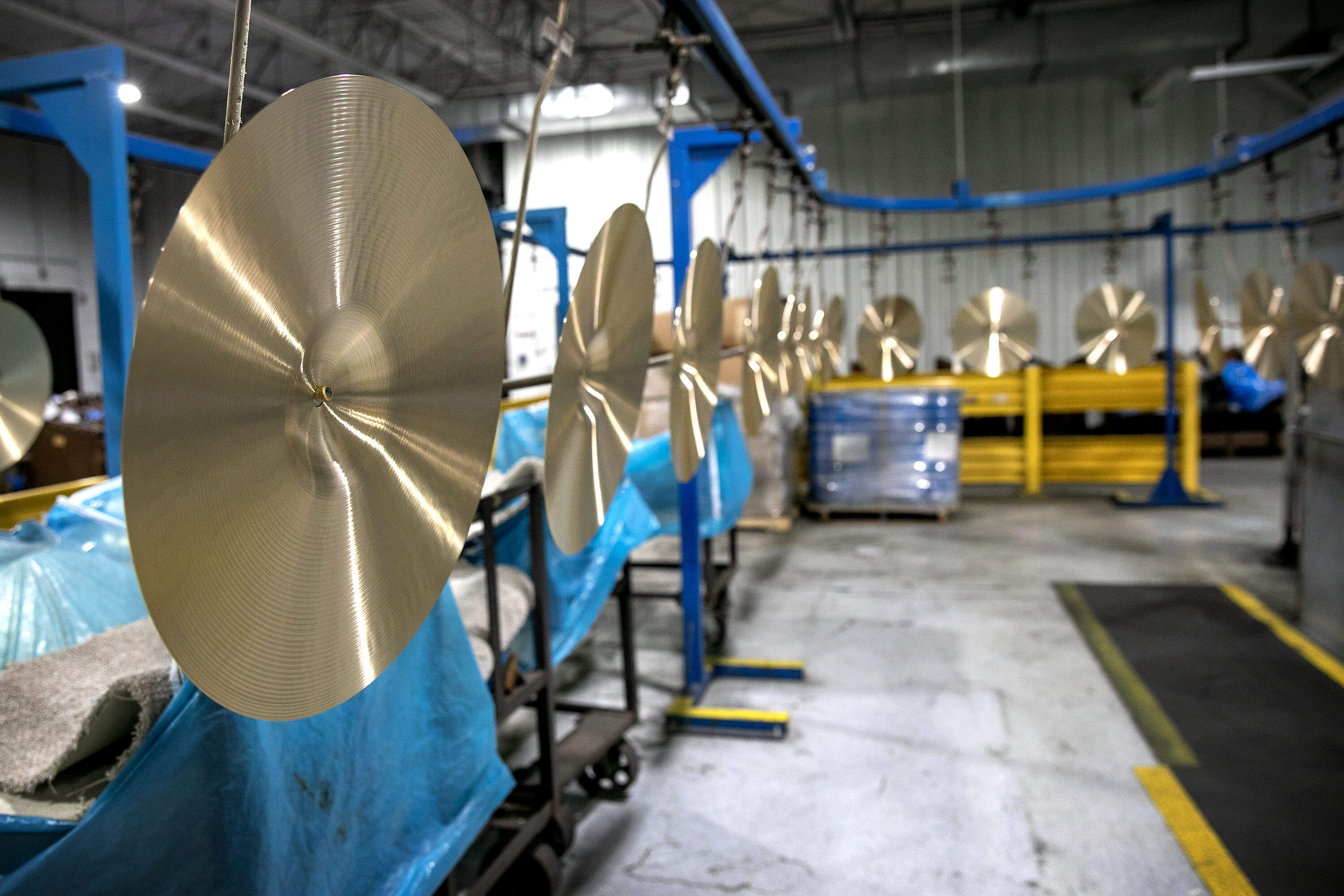

Zildjian’s manufacturing has developed to maintain up with demand for its 600 fashions of cymbals bought in additional than 100 international locations. In accordance with the corporate, it takes a minimal of 15 folks to finish a single cymbal. In the present day machines hammer the alloy devices, however their types are nonetheless finessed by expert craftsmen.

Earlier than every cymbal is deemed worthy for artists or retail it has to go a human ear take a look at. That’s Eric Duncan’s job. “That is the make or break level,” he stated within the testing room.

One after one other, Duncan lifted cymbals from a rack to check their sound with a pristine instance. “We take a look at anyplace from 1000 to 4,000 cymbals a day, relying on how busy we’re.”

Every permitted cymbal will get stamped with the household title. They name it the “Zildjian kiss.”

Whereas a lot of the cymbal-making course of hasn’t modified for the reason that 1600s, Debbie Zildjian stated enlargement and innovation have been vital for the corporate’s longevity. She pointed to merging with the drumstick firm Vic Firth in 2010 and this yr’s debut of Zildjian’s first digital drum package.

“We’ll by no means abandon the acoustic,” Debbie stated, “however digital is the wave of the longer term.”

Debbie loves sharing her household’s storied previous, however, as a keeper of their closely-guarded 400 yr outdated alloy she doubled down, “The key half will stay a secret.”